Adapting to the shift in safety needs has become the primary focus for many business owners, specifically those in multifamily realty, commercial offices, and industrial facilities. Meeting the demand for clean, safe, and effective measures depends on you and the efforts you take. From your team to those who occupy your buildings, your company’s survival depends on what you implement to ensure a clean and safe environment.

The safety protocols you need to meet now are evolving into the industry standards for facilities management. As a business owner or building manager, you need permanent solutions that will protect your environment at all times. The answer lies in Engineered Infection Protection (EIP), a comprehensive approach to design and engineering geared toward infection prevention.

What Is EIP?

Engineered Infection Protection, or Engineered Infection Prevention, is a new term for most facilities managers. It involves using smart engineering, automation, and facility design solutions to prevent infection transmission in the workplace. The concept originated in the healthcare industry, a sector with more need for infection control measures than most workplaces. These days, when all companies need to adopt new strategies to protect their teams, EIP is vital for any commercial or industrial workplace. It’s commonly employed in multifamily housing, commercial offices and venues that host large crowds.

Examples of EIP in Action

EIP originated in the healthcare industry, since healthcare facilities must reduce the transmission of contaminants between patients or from patients to team members. The risk of healthcare-associated infections (HAI) among patients is surprisingly high. On any given day, one in 31 patients currently hospitalized has at least one HAI. The use of EIP for healthcare reduces this risk through engineering controls.

The goal of EIP is to use engineered tools to limit the spread of infection. In hospitals and other facilities, EIP strategies provide continuous disinfection in bathrooms, patient rooms, and other areas where pathogens congregate.

Whether you’re in healthcare or another industry, looking at how EIP is applied in a typical hospital can give you a deeper understanding of the concept. Some of the EIP disease prevention and facility disinfection solutions used in hospitals include:

- Hand hygiene infrastructure: Hand hygiene is crucial to preventing HAIs. Doctors and nurses should wash their hands thoroughly between patients. Unfortunately, this may not always happen to the extent it should, especially when sinks and hand sanitizing stations aren’t nearby. Some engineering controls, such as installing hand sanitizer dispensers at every patient room door and bedside, would make this easier.

- Sterilization areas: Areas where hospital team members sterilize tools or equipment need a practical design to promote a clean workflow. They should have a unidirectional flow from dirty to clean. Sterilizers might include ultraviolet (UV) lights, steam sterilizers, hydrogen peroxide plasma sterilizers, or ethylene oxide sterilizers.

- Touchless automation: High-touch surfaces spread contaminants quickly. EIP incorporates touchless sink faucets and sanitizing stations to curb this. It can also integrate automatic flush toilets and touchless paper towel dispensers instead of warm air dryers. At main entrances, automatic doors can also help limit the spread of contaminants.

- UV sterilizing lights: Healthcare facilities can achieve sterilization through lighting. While UV lights have long been used to disinfect tools, they can also be installed in air handling systems to prevent bacteria and other contaminants from entering the air supply.

While every industry and building is different, many of these same principles come into play when EIP is implemented in other commercial properties. Any building benefits from touchless automation and UV sterilizing lights in air handling systems, and these measures are critical for pathogen mitigation in any indoor space.

EIP and the Effectiveness of Engineering Controls

The theory behind EIP is steeped in the hierarchy of controls. This hierarchy is an approach to infection and injury prevention used by both the Centers for Disease Control and Prevention (CDC) and the Occupational Safety and Health Administration (OSHA). The hierarchy of controls lists the types of controls you can use to protect workers from the most effective to the least effective.

The most effective control is elimination. In the case of COVID-19, elimination involves quarantining infected people and preventing them from entering the building. Unfortunately, that’s not always possible. In a healthcare setting, infected patients must enter the building. In multifamily housing units, an infected person will need to quarantine within their own living space. When the person has no symptoms, it’s not practical to prevent them from entering. In those cases, follow the hierarchy, which includes five steps:

- Elimination: Physically remove the hazard or source of infection.

- Substitution: When possible, replace the hazard with something less harmful. This step is less applicable for preventing infections.

- Engineering controls: Isolate people from the hazard.

- Administrative controls: Change the way people work.

- Personal protective equipment (PPE): When no other controls will work, protect people using PPE.

Despite the general public’s newfound familiarity with masks and other PPE, they’re the least effective way to control the spread of infection. As an administrative control, social distancing in the workplace is more effective. Since elimination and substitution aren’t as practical for pathogen mitigation on the premises, implementing engineering controls is considered best practice for preventing diseases and infection. That’s where Engineered Infection Prevention comes into play.

Engineered Infection Protection: The Answer to Pathogen Mitigation Concerns

EIP is essential in all indoor environments. Businesses from healthcare and residential facilities to offices and warehouses must use EIP techniques to limit infections in the workplace. A few simple engineering controls can help stifle the spread of illnesses.

For example, routine disinfection procedures are a crucial part of engineering control. However, many disinfecting solutions require people to follow proper protocol. Workers disinfecting surfaces need to apply the chemical to every surface without missing a spot and observe the appropriate dwell time. The biggest flaw with traditional surface disinfection is that it must be repeated often. Between treatments, surface pathogens have time to flourish.

Continuous disinfection can significantly boost the effectiveness of disinfection procedures. One of the ways to disinfect continuously is to use antimicrobial surfaces. Another aspect of EIP surface disinfection is prioritizing touchless automation for sinks, trashcans, soap dispensers, doors, and other facility operations. Offices and other commercial buildings can use ultraviolet germicidal irradiation (UVGI) lighting to disinfect surfaces continuously.

Another common and easy-to-implement engineering control is the use of partitions, barriers, or sneeze guards to prevent airborne pathogen transmission. These engineering controls are undoubtedly more effective than using masks alone. However, they won’t necessarily prevent the spread of aerosolized viruses. Air quality control engineering can make the air safer to breathe in the workplace. Some airborne contamination EIP solutions include UVGI lighting in the air handling systems, high-efficiency particulate air (HEPA) filtration, and air ionization to kill viruses on contact.

Why EIP Is Important to Your Business

Engineered Infection Protection uses design as its primary method of disease prevention. Designing buildings to limit the spread of viruses and other pathogens continuously has many benefits to your organization, including:

1. Increased Effectiveness and Reliability

Administrative controls and PPE both rely on people to work. Cough and sneeze etiquette, social distancing, and hand washing all require your team’s cooperation and perfect execution. Likewise, PPE and cloth face coverings also rely on their wearers to don them properly. Let’s face it — people make mistakes. Engineering controls make a lot fewer. Additionally, continuous measures, like those involved in an Engineered Infection Prevention program, constantly reduce viral spread. They keep working to combat viruses on surfaces and in the air, even when building occupants forgo social distancing or don’t wash their hands properly.

2. Permanent Solutions

Many facilities managers have ramped up their use of surface disinfection in the last few months. While there are no set guidelines for how often to disinfect high-touch surfaces throughout your building, it must be done frequently. After thoroughly sanitizing an area, it just takes one infected person to reintroduce a contaminant. Disinfecting chemicals cannot continue killing viruses or bacteria after treatments have been applied. Regular surface cleaning and disinfection may require nearly constant oversight. EIP and continuous disinfection programs are permanent, and you don’t need to make any changes in your facility management workflow other than maintaining the sterilization equipment.

EIP’s permanence resolves the issues left unaddressed by temporary fixes. For example, one control many businesses have tried is working from home. However, some companies require in-person or on-premise interactions and need a way to return to work safely. Here, EIP solutions are crucial. They provide permanent infection control solutions to pathogen mitigation concerns. Your business can reduce the risk of shutting down in-person operations due to an outbreak.

3. Improved Working Conditions

Implementing infection prevention and control measures can do more than mitigate risks. They can become a strategic advantage for your company. As a facility manager, you can attract more occupants to your building when you take effective design and engineering measures to prevent the spread of infection. Companies that operate in buildings with EIP controls attract more employees by creating safer conditions. You’ll ensure your building occupants are more comfortable and healthy, which, in turn, boosts their productivity at work or satisfaction with their living arrangements.

SitelogIQ’s Approach to EIP

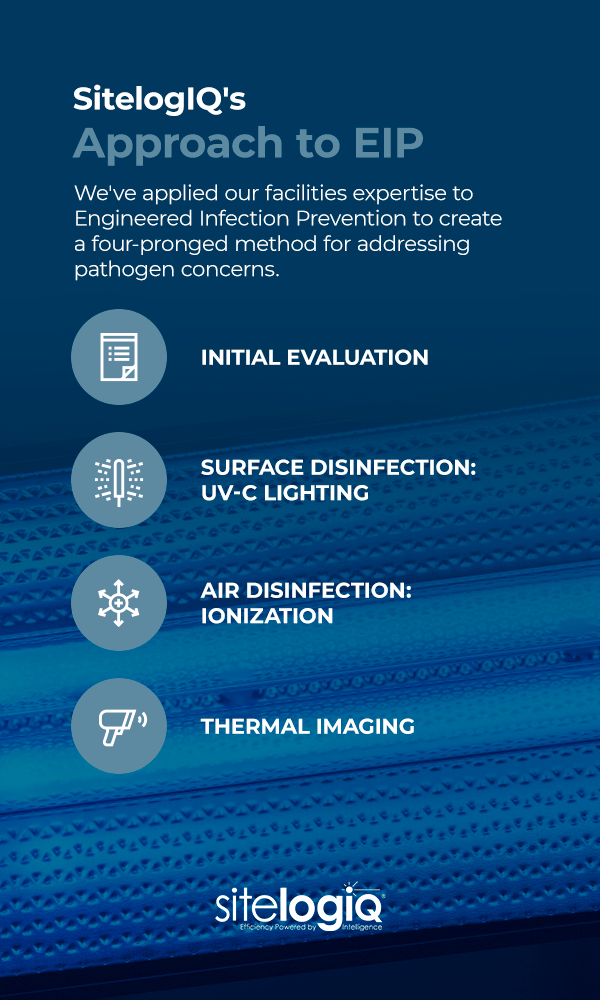

At SitelogIQ, we pride ourselves on creating custom facility-wide programs for various needs. Whether your goal is energy efficiency, sustainability, or lighting and air quality control, we can develop an industry-leading solution. We’ve applied our facilities expertise to Engineered Infection Prevention to create a four-pronged method for addressing pathogen concerns.

1. Initial Evaluation

Every facility has a unique layout, varying levels of risk, and different areas for potential exposure. Mitigating the spread of pathogens requires a program that addresses your building’s needs and takes advantage of the infrastructure you already have when possible. At SitelogIQ, we specialize in personalized, comprehensive solutions to Engineering Infection Protection, which starts with evaluating your current needs.

First, we examine the overall market trends in pathogen mitigation and your industry. The solutions we suggest for a healthcare facility may look different from those required in a manufacturing plant, an office building, or a residential complex. Next, we look at your needs. Business owners across industries must shift from short-term viral protection measures to permanent solutions to address pathogen mitigation concerns.

Our goal is to ensure a clean and safe facility. As part of our evaluation, we’ll develop a comprehensive solution to support safety, security, resiliency, energy and operational efficiency, and sustainability. We can prioritize what’s needed for your company. To give you peace of mind, we serve as an extension of your team to create healthy, comfortable indoor environments that promote productivity, increased output, and improved experiences. We’ll help you make critical decisions for your building while maintaining your productivity and planning for tomorrow’s changes.

2. Surface Disinfection: UV-C Lighting

Our EIP approach to surface disinfection involves state-of-the-art far-ultraviolet (UV-C) lighting. While healthcare facilities have used other UV lighting types to disinfect unoccupied spaces and surfaces, revolutionary UV-C lighting is safe for use in occupied areas. A recent Columbia University Irving Medical Center study found a low-exposure to UV-C lighting could kill 99.9% of two airborne coronavirus strains. The researchers concluded a continuous use of UV-C lighting in occupied spaces could kill:

- Ninety percent of viruses in eight minutes.

- Ninety-five percent of viruses in 11 minutes.

- Ninety-nine percent of viruses in 16 minutes.

- Nearly 100% of viruses in 25 minutes.

UV-C lighting is powerful enough to work on airborne viruses, and use on surfaces can be just as effective. On high-touch surfaces in areas with multiple people, it can kill bacteria and viruses in seconds. We use UVGI lighting in HVAC systems to combat surface contamination alongside airborne contamination. Our custom approach to surface disinfection also includes incorporating antimicrobial surfaces and touchless automation.

3. Air Disinfection: Ionization

Air ionizers are an air quality control measure that introduces ions to charge the small particles in a room. These small particles, such as smoke, can then be filtered into a collector to remove them from the air. Air ionizers have a proven ability to kill airborne bacteria, making them an excellent additional measure for indoor air sterilization. Air ionizers combat recycled, polluted air by cleaning airflow with ions and reactive oxygen species (ROS).

Our comprehensive air disinfection solution includes air ionization as well as UVGI in upper-air zones and HVAC units, HEPA filtration, and humidification. Our method results in cleaner, irritant-free air as well as a proven approach to air disinfection.

4. Thermal Imaging

The third challenge facilities have with pathogen mitigation is screening. For a high-occupancy building, it’s a slow process to check everyone’s temperatures as they enter. Screening building occupants by a thermometer, even a touchless one, places the screener at risk since they cannot stand 6 feet away from the people they’re screening. Relying on self-monitoring presents other problems since there’s less oversight. Inefficient or ineffective temperature checking impacts an entire facility.

Many viruses, from SARS-CoV-2 to the seasonal flu, cause fevers. The typical cutoff point is any body temperature above 100.4 degrees Fahrenheit. Barring entry to people expressing fevers is an excellent way to reduce the viruses entering your facility. Creating an accurate body temperature monitoring system that won’t disrupt workflows is crucial.

SitelogIQ’s EIP solutions use thermal imaging. We offer two options — a high-traffic venue screening and rapid, no-contact individual screenings, both powered by thermal imaging cameras. The technology uses heat signatures to form an image or video based on temperature differences. It lets you read the exact body temperature of any person who crosses its path. We can set up thermal imaging throughout your facility to analyze foot traffic and identify people exhibiting an elevated body temperature who may be spreading viruses throughout your facility.

Learn More About Our COVID-19 Solutions

As your facility transitions to permanent disease prevention solutions, SitelogIQ is your trusted partner. We understand the impacts your property has faced during this challenging time, which is why we’re here with short-term and long-term infection control solutions for businesses. We can coordinate emergency funding tracking and develop Contingency and Risk Assessment Plans for your location. We also offer a range of pathogen mitigation technologies and Engineered Infection Protection.

Contact SitelogIQ for more information about how EIP can help your business.